Category Archives: Helpful Tips

Where Do We Use Expansion Joints in Piping?

Pipe Expansion Joints

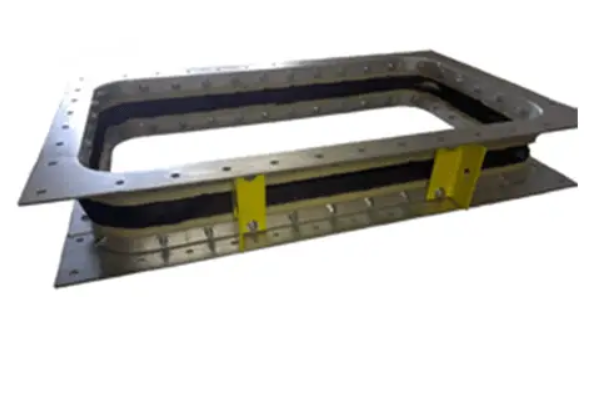

Pipe expansion joints are useful in a variety of industrial sectors such as energy production, water treatment, paper industry, oil & gas, chemical industry, etc. The application of expansion joints is extensive in all categories of manufacturing units for making the transportation of gases and liquids operative and convenient. The constituent parts of expansion joints are liners, bellows, cover, limit rods, and end fittings. The inner area of the expansion joints will have liners, which is to safeguard the interior surface from the possibility of wearing away. The incorporation of the same will keep in check the lateral, angular, and axial motions in piping systems. One main point to reckon here is that each of the manufacturing units will have its distinctive property and requirements.

Where Do We Use Expansion Joints in Piping?

Piping systems are par for the course of every manufacturing industry, irrespective of the items produced. The practical use of these pipes is to transport varied types of gases and liquids from a specific place to a new location. Such a transporting system is an essential mechanism in almost all manufacturing units, and devoid of this, the proper functioning of the related plant becomes impractical. Nevertheless, the erection of the pipe system will be quite different in different manufacturing plants. The structure of the system depends on practical needs; some will be for carrying high-temperature substances, whereas some others will be for transferring materials that have low-temperature. Only by using flawless pipe expansion joints, one can maintain the flow within the system precisely perfect. For this, companies must use technically perfect expansion joints, created by established manufacturers; this point is vital.

The use of pipe expansion joints is imperative in piping systems because of varied reasons. The application of the same becomes vital when the expansion loops become unfeasible as regards the absorption of thermal expansion. It’s available in different shapes. Expansion joint acts as a flawless shock and vibration absorber; besides it tones down the noise, alleviate the anchor stress, and balance the probability of misalignment. In general, you can find three types of expansion joints, namely, rubber, metal, and fabric.

These expansion joints are for varied purposes, and one will have to choose the joint precisely in line with the practical requirement and the nature of the application. That said, it is only prudent to buy the needed expansion joints from a reliable dealer who has earned the market reputation. Remember, a precise manufacturing process is essential here, and there must not be any mistakes. Even a small mistake as regards the fabrication or specifications will pay the way for the collapse of the system.

Buy Pipe Expansion Joints Online

One can buy expansion joints through online stores, and this is the best form of shopping in our time. Social distancing has become vital these days because of the invasion of the novel corona virus. However, it’s of great importance that companies must buy the same from the stores of dependable merchants; this is imperative to ensure the quality of the same. Reputable online stores will sell only quality pipe expansion joints manufactured by established companies.

Consider the Authenticity of the Trader

The trader from whom you buy the pipe expansion joints must hold a reputation as a reliable agent in selling pipe valves, fittings, etc., required for electrical, mechanical functions as regards industries related to refining, offshore, hydrocarbon, power, chemical, construction, engineering, etc. There must be top customer service, which is a must; remember, only when you get the needed technical support at the right time, the manufacturing process will go intact. These days, leading dealers who sell expansion joints will be ready to give online quotes, which will be practically useful for you to pick the most affordable online store. You will just have to apply through the website; the sales team will contact you at the earliest. Taking online quotes is the best practical option to compare the products available at different online stores as regards the quality, customer service, and related price tags. Thus you can pick the best option.

CNC Machining Services – Three Tips to Choose the Right Company

CNC machining has revolutionized the metal fabrication process in the past few decades. Manufacturing industry relies heavily on the CNC machining for the mass production of metal parts. That’s why choosing the right CNC machining company is very important for the success of a manufacturing business.

Here are the three tips to choose the right CNC machining company:

Licensing and Experience

The first and foremost thing you need to ensure is the company you are interested in must have a valid license to operate in your state. State and local government authorities are responsible for the licensure of CNC machining services companies in your area. Regulating authorities follow strict rules and guidelines for the licensure of CNC machining shops. A valid license ensures that the company has trained and skilled staff, and complies with industry norms in the manufacturing process.

And once you have checked the certification and license of the company, ask questions about the experience of your CNC machining shop. When it comes to the mass production of high precision metal components, there is no substitute for experience. Find a company that has a team of experienced engineers, quality analysts, and machine operators. When you hire an experienced CNC machining company, you don’t have to worry about the quality of metal components and unnecessary delays in delivery of the project.

Equipment and Technology

A CNC machining company is as good as their engineers, machine operators, and equipment used for production. Type of technology your CNC machine shop is using has a great impact on the quality of metal components and cost of production. Ask your shop management about equipment and technology they are using for fabrication.

Modern CNC machines are highly efficient and have less defect rate. Also, if you want to make changes in the design of metal parts, modern CNC machines have various software capabilities that allow you to modify the design. Make sure your CNC machine shop uses up-to-date modern technology. Better technology makes manufacturing process highly efficient, cost-effective, and fast. Also, ask your shop management about the type of material they work with because different CNC machining companies work with different materials.

Previous Work and Prototyping

Almost every CNC machining company claims that they are the best in the industry. The best way to find out is to have a look at samples of their previous work. A good CNC company will be eager to show samples of metal components produced in their shop. When you see samples of previous work, you will get a fair idea of their attention to detail and quality of the work.

And before placing large orders, you can use prototyping. During the prototyping process, you can determine the company’s capability to communicate and understand your needs. If you are satisfied with the prototype, then you can hire the CNC machining services you are interested.

These are the three tips you can keep in mind while choosing your CNC machining company.

Why hire CNC machining services?

Hiring a CNC machining company has enormous benefits. You don’t have to invest a substantial amount of money in purchasing, operating, housing, and maintaining the equipment. Operational costs of in-house production can be overwhelming for many businesses. On the other hand, outsourcing CNC machining work can get the job done at a fraction of the cost of in-house production.

More importantly, it allows you to focus on the core activities of your business. Once you have chosen a right CNC machining company, you do not have to worry about managing the production process. Your CNC machine shop will be responsible for the quality control and delivering project in specified deadlines.

In the end…

Fabrication is the most important step in the manufacturing process. It has a direct impact on the success of your business. Therefore, it is necessary that you should spend some time on research before hiring CNC machining services for your manufacturing needs.